Heart And Sole

Text: Adriana Giuffrida Images: Benjamin Lichtenstein

Text: Adriana Giuffrida Images: Benjamin Lichtenstein

I don’t know why but I always assumed that shoes were never actually handmade by people. I dont know what I thought the process was, I guess I thought there were shoemaking robots churning out these perfect vessels that drive women wild. That was until I heard of Emma the Shoemaker. Emma Shirgwin is a Melbourne based shoemaker who had the clog on high rotation before Chanel knew what hit them. Her designs are comfortable, unique and lustworthy. I chatted to Emma about her journey into making shoes and the trials and tribulations that come with creating such a fascinating product in Australia.

Adriana Giuffrida: Tell us how you began making shoes.

Emma Shirgwin: It started with an idea through a love of shoes, after exploring this I landed at RMIT Dawson street in Melbourne chatting to the teachers about the course, I then went overseas traveling Europe for a year and whilst there I attended a short course at Cordwainers College, which is a reputable course that started many of today’s shoe makers careers. Once I returned I did the course here in Melbourne, but this was only offered two days a week. I was finding that too disjointed, so I then volunteered my time with a shoemaker here called Preston & Zly, where I befriended another shoemaker, who told me about a brilliant two year, full time course in Adelaide, so I decided to pack my life up and move to Adelaide which was the best thing I ever did.

AG: So your journey into making shoes has taken to you from Melbourne to Adelaide and also London, what did each of these courses offer you?

ES: The London course was very short so it gave me an introduction to the basics to see if I really wanted to explore this further, as with the Melbourne course but the Adelaide course was amazing and I use all I was taught there today. This course gave me the confidence to make shoes outside of the classroom independently.

AG: What is the difference between the ‘Lunati’ process that you use to make shoes, and other methods?

ES: It is a comprehensive method for me because with this process the pattern is made to fit the Last (the mould I use to make shoes on) which you match to the particular foot measurements, so for this reason the leather upper moulds easily onto the Last. Also we make a paper pattern first. I am a visual person so I need to see it three dimensionally to fully grasp the design. Other methods are designed to fit the foot measurements, so it does not always fit the Last very well so there is a lot of pulling and tugging for it to fit snug.

AG: I can imagine the finished product of seeing a shoe, must be quite rewarding. What do you find is the most exciting aspect of making shoes?

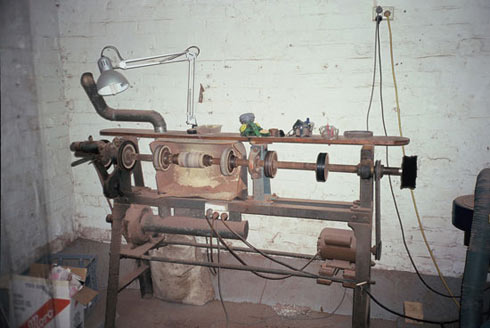

ES: I love every aspect of the shoemaking, apart from grinding the heels and soles which is very dirty work, but sometimes I cant believe I have made it. It is very rewarding seeing this object transform within my two hands and keeps me working through the tough times.

AG: How long does it take to complete one pair of shoes?

ES: This depends on so many factors, I custom make all of my shoes, so sometimes there is a lot of modifying the Last to fit the customer and this takes time. Also sometimes the pattern will also need adjustments. When all the patterns fit, and the Lasts are a perfect fit, and I have all the materials, I can make three pairs in four days but this is working four 10-hour-days with only a small break.

AG: You make bespoke shoes as well as designing your own. Do you find a lot of inspiration from doing projects for other people?

ES: Yes and no. I prefer making my designs as I know the desired results and I enjoy making these styles. Designs that are brought to me by others can be fun and challenging if I like the styles.

AG: Your materials are sourced in Melbourne, do you ever find this limiting, or is this part of the charm?

ES: This can be limiting! I have so many ideas that I end up simplifying due to not finding what I want. Especially with heels they are very boring here so that is why I usually have wooden ones made for me, there is one guy who does this so I have to order months in advance, or sculpt my own leather stacked heels. Apparently in China there is every leather finish that you can imagine! Even simple things like nice shoe boxes are not available here anymore and have to be ordered in the thousands through China.

Sometimes these limitations can make you more imaginative and inventing new methods to complete the design pushes you, but can also drive you to frustration.

AG: What would you describe as your dream shoe?

ES: A shoe that I could make with no time limits, no material cost restrictions, and with leather and trims sourced from all over the world.

AG: If you could work with any other shoemaker in the world in a collaborative way, who would it be?

ES: I would have to say Vivienne Westwood’s shoemakers.

AG: What’s next for Emma the Shoemaker?

ES: New designs when I have the time. I am also starting a company with three shoemaker friends, with all our designs being produced offshore.

Emma The Shoemaker

Next story: Sam Lipsyte: The Secret Is In The Satire